Manufacturing

Enhance your manufacturing efficiency with our cutting-edge IT solutions designed to streamline operations, reduce costs, and drive innovation. Our advanced software provides real-time insights and automation to optimize your production processes and ensure superior quality and performance.

Trusted by Enterprises, Startup like :

Challenges Affecting Manufacturing

Insights and Solutions for Overcoming Operational, Technological, and Supply Chain Obstacles to Enhance Efficiency and Drive Industry Advancement

Legacy Systems and Infrastructure

Many manufacturing companies operate on legacy systems that have been in place for decades. These outdated infrastructures are often incompatible with modern technologies, making integration complex and costly. Upgrading or replacing these systems requires substantial investment, both in terms of capital and time, and often entails a steep learning curve for employees.

Data Management and Integration

Modern manufacturing processes generate vast amounts of data from various sources, including IoT devices, sensors, and enterprise resource planning (ERP) systems. Managing, integrating, and analyzing this data to derive actionable insights is a significant challenge. Many manufacturers struggle with data silos, inconsistent data formats, and inadequate data governance practices, which hinder their ability to fully leverage the potential of digital technologies.

Skills Gap and Workforce Training

The rapid pace of technological advancement has created a skills gap in the manufacturing workforce. Many workers lack the necessary skills to operate new technologies such as AI, machine learning, and robotics. Bridging this gap requires ongoing education and training programs, which can be resource-intensive and time-consuming. Additionally, attracting and retaining tech-savvy talent in a traditionally non-tech industry is a persistent challenge.

CyberSecurity Threats

With the increased adoption of IoT devices and cloud computing, the manufacturing industry is more vulnerable to cyber threats than ever before. The interconnected nature of modern manufacturing processes exposes critical systems to potential attacks, which could lead to data breaches, operational disruptions, or even physical damage to manufacturing equipment. Ensuring robust cybersecurity measures is a significant challenge that requires continuous monitoring and updating.

Supply Chain Disruptions

The global nature of supply chains means that any disruption, whether due to geopolitical tensions, natural disasters, or pandemics, can have a significant impact on manufacturing operations. Technology can offer solutions to mitigate these disruptions, such as predictive analytics and supply chain visibility tools, but implementing these solutions effectively requires overcoming several challenges, including data integration and real-time monitoring capabilities.

Resistance to Change

Cultural resistance within organizations can be a significant barrier to technological adoption. Many employees may be wary of new technologies, fearing job displacement or increased workload. Overcoming this resistance requires strong leadership, clear communication of the benefits of technology adoption, and the implementation of change management strategies that involve all stakeholders.

What tools we offer to fight against Manufacturing Challenges

Discover Our Advanced Tools for Overcoming Challenges and Enhancing Learning Outcomes Seamlessly.

Best Solution for Manufacturing

Discover the Premier Solution for Streamlining Manufacturing Processes, Enhancing Efficiency, and Reducing Costs. Our cutting-edge technology delivers tailored solutions to meet your industry’s specific needs, driving operational excellence and fostering sustainable growth.

Workforce Training and Development Platforms

Our platforms utilize e-learning, virtual simulations, and on-the-job training modules to upskill workers in the latest technologies, including robotics, AI, and data analytics. These platforms are designed to be user-friendly and flexible, allowing manufacturers to scale their training efforts as needed.

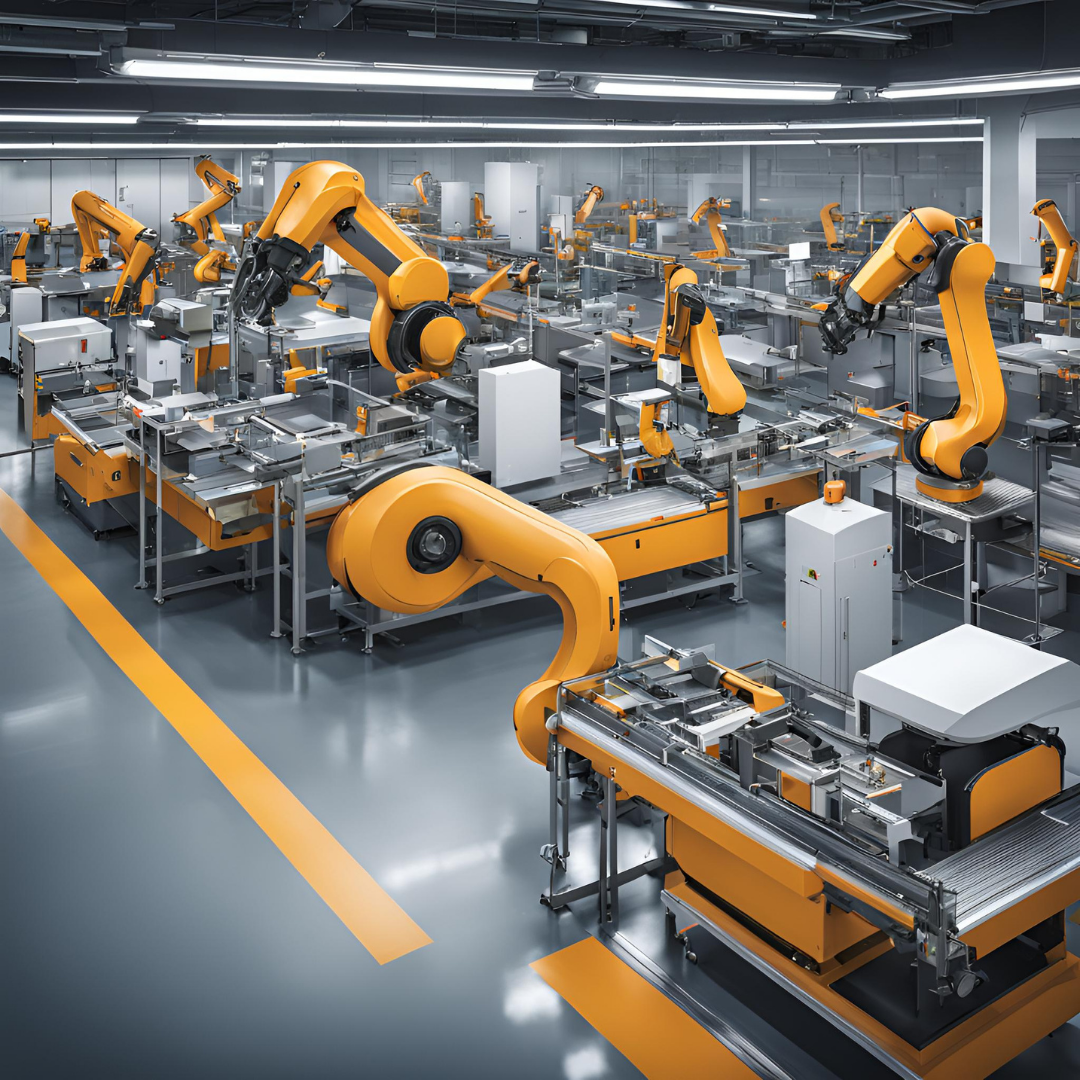

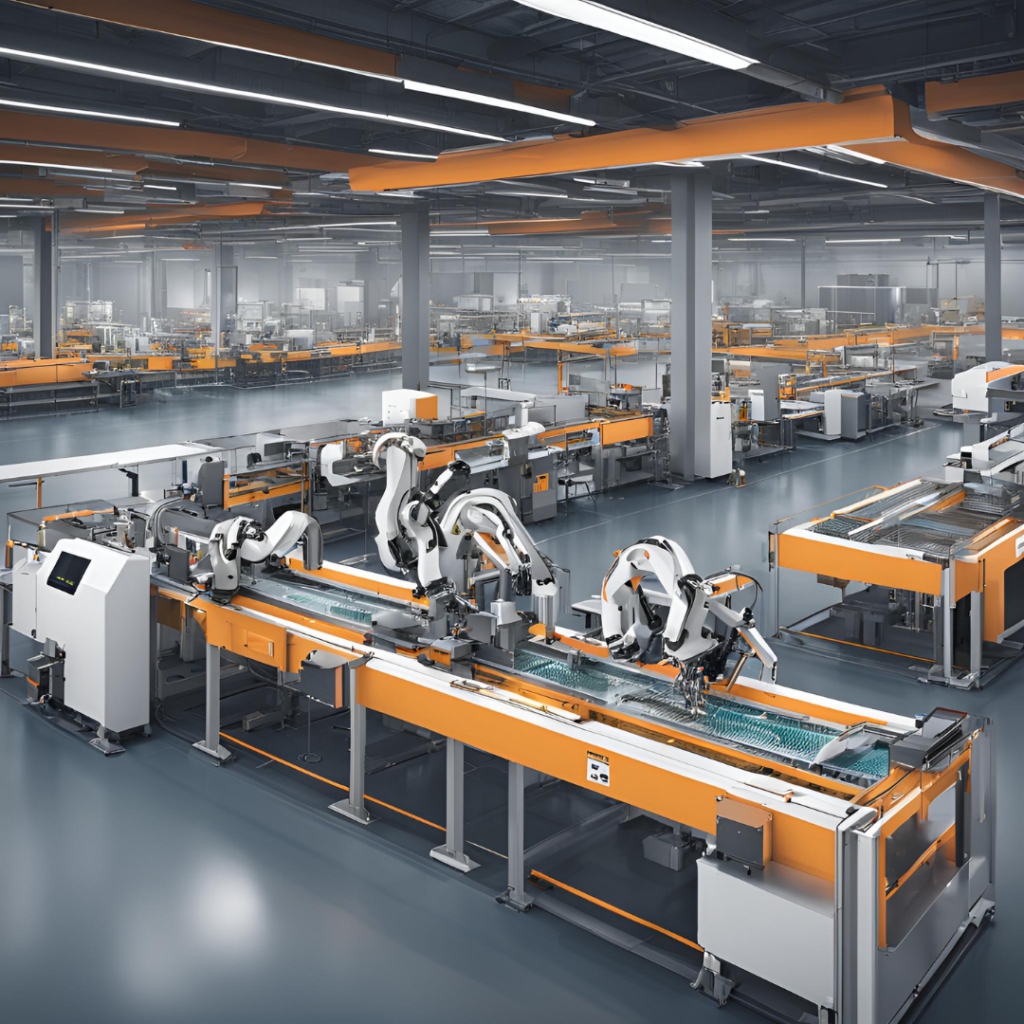

Manufacturing Automation and AI-Driven Analytics

Our Manufacturing Automation and AI-Driven Analytics software helps manufacturers optimize their production processes, reduce costs, and increase efficiency. This solution includes advanced robotics, predictive maintenance tools, and AI-powered analytics that provide real-time insights into production performance.

Employee Engagement Platforms

To overcome resistance to change, we offer Change Management Tools and Employee Engagement Platforms that support the smooth implementation of new technologies. Our tools include communication and collaboration features that keep employees informed and engaged throughout the transformation process.

Supply Chain Visibility and Predictive Analytics Software

This solution includes predictive analytics tools that forecast potential supply chain issues and offer recommendations for alternative sourcing or production strategies. By enhancing supply chain transparency, manufacturers can respond quickly to changes and maintain operational continuity.

Our Custom Manufacturing Solution

Revolutionize your production process with our Custom Manufacturing Solution. Tailored to meet your specific needs, our solution enhances efficiency, reduces costs, and ensures high-quality output. Experience seamless integration and robust performance designed to drive your business forward.

Enterprise Resource Planning (ERP) Systems

Our ERP solutions offer comprehensive integration of core business processes, including inventory management, procurement, production planning, and financial accounting. By streamlining operations and facilitating real-time data access, our ERP systems enable manufacturers to optimize resource allocation, reduce operational costs, and improve overall efficiency.

Manufacturing Execution Systems (MES)

Designed to bridge the gap between enterprise systems and shop floor operations, our MES solutions provide real-time visibility into manufacturing processes. They enable manufacturers to monitor production performance, manage work orders, track inventory, and ensure quality control. With advanced analytics and reporting capabilities, our MES solutions help identify and address bottlenecks, enhance productivity, and ensure compliance with industry standards.

Supply Chain Management (SCM) Software

Our SCM software offers end-to-end visibility and control over the supply chain, from raw material sourcing to final product delivery. By leveraging predictive analytics and real-time tracking, manufacturers can optimize inventory levels, forecast demand more accurately, and mitigate supply chain disruptions. Our solutions also facilitate supplier collaboration and enhance procurement processes.

Industrial IoT (IIoT) Solutions

Harness the power of the Industrial Internet of Things with our IIoT solutions, which connect and monitor manufacturing equipment through sensors and smart devices. These solutions provide real-time data on equipment performance, predictive maintenance alerts, and process optimization insights. By enabling data-driven decision-making, our IIoT solutions help enhance operational efficiency and reduce downtime.

Quality Management Systems (QMS

Ensure consistent product quality and regulatory compliance with our QMS solutions. These systems streamline quality control processes, manage non-conformance issues, and facilitate corrective and preventive actions (CAPA). By providing tools for detailed reporting and documentation, our QMS solutions help maintain high standards and improve overall product quality.

Human Resource Management Systems (HRMS)

Our HRMS solutions support the management of human capital within manufacturing organizations. Features include workforce scheduling, payroll processing, performance management, and employee training. By optimizing HR processes, our solutions help manufacturers attract, retain, and develop skilled talent, which is crucial for maintaining operational excellence.

Cybersecurity Solutions

Protect your manufacturing operations from cyber threats with our robust cybersecurity solutions. Our software includes tools for threat detection, network security, data encryption, and vulnerability management. By safeguarding critical systems and data, our cybersecurity solutions help mitigate risks and ensure the integrity of manufacturing operations.

Technologies at the Forefront Off Innovation

Discover the Technologies at the Forefront of Innovation Shaping Tomorrow’s Digital Landscape Today.

- Understanding Client Needs: Collaborate with retail stakeholders to identify business goals, customer expectations, and operational challenges.

- Market Research: Analyze market trends and competitors to inform the development of innovative retail solutions.

- Technical Specifications: Define the technical requirements, including scalability, integration with existing systems, and platform choices.

- Architecture Planning: Design a scalable and robust IT architecture tailored to the retail environment, incorporating front-end and back-end systems.

- User Experience (UX) Design: Create intuitive and responsive user interfaces that enhance customer interaction and streamline in-store and online experiences.

- System Integration: Plan for seamless integration with existing retail systems such as ERP, CRM, and POS systems.

- Custom Software Development: Build tailored applications, including e-commerce platforms, inventory management systems, and customer engagement tools using technologies like React, Node.js, and cloud-based solutions.

- API Development: Create APIs for smooth data exchange between various retail systems and third-party services, enabling omnichannel retail experiences.

- Mobile App Development: Develop mobile apps for customer engagement, loyalty programs, and in-store navigation, ensuring cross-platform compatibility.

- Functional Testing: Ensure that all features work as intended, focusing on transaction processing, inventory updates, and user experience.

- Security Testing: Conduct rigorous security testing to safeguard customer data and prevent breaches, including vulnerability assessments and penetration testing.

- Performance Testing: Optimize system performance to handle high traffic volumes, especially during peak shopping seasons.

- Cloud Deployment: Deploy the retail solution on cloud platforms to ensure scalability and flexibility, with options for hybrid or on-premises deployments as needed.

- Data Migration: Safely migrate existing data from legacy systems to the new platform, ensuring data integrity and minimal disruption.

- Go-Live Support: Provide support during the launch phase, monitoring the system for any issues and ensuring a smooth transition.

- System Monitoring: Continuously monitor the system for performance, uptime, and security, using advanced analytics and monitoring tools.

- Updates and Maintenance: Regularly update the software to add new features, improve performance, and address any security vulnerabilities.

- Customer Support: Provide 24/7 support for any technical issues, ensuring minimal downtime and uninterrupted retail operations.

- Data Protection: Implement robust data protection measures, including encryption, secure access controls, and compliance with data privacy regulations like GDPR.

- Threat Detection: Use advanced threat detection systems to identify and mitigate potential security threats before they impact the business.

- Incident Response: Develop and maintain a comprehensive incident response plan to quickly address any security breaches or system failures.

- Customer Feedback: Regularly gather feedback from retail clients and customers to identify areas for improvement and new feature development.

- Innovation: Stay ahead of industry trends by continuously exploring new technologies such as AI, IoT, and blockchain to enhance retail solutions.

- Scalability: Plan for future growth by ensuring the IT infrastructure can scale with the business, accommodating new locations, products, and customer demands.

Why Choose us for your Organization?

In the rapidly evolving landscape of manufacturing, staying ahead demands not only innovation but also a partner who understands the unique challenges of the industry. At Ravalent, we provide cutting-edge software solutions tailored specifically for the manufacturing sector. Our solutions are designed to enhance operational efficiency, streamline processes, and drive growth.

Our deep expertise in manufacturing technology enables us to offer solutions that integrate seamlessly with your existing systems, ensuring minimal disruption while maximizing productivity. We leverage advanced analytics, IoT, and automation technologies to deliver actionable insights, optimize resource allocation, and improve decision-making.

What sets us apart is our commitment to personalized service and support. We work closely with you to understand your specific needs and develop solutions that align with your strategic goals. Our dedicated team of experts provides continuous support and updates, ensuring that your technology evolves with the industry.

Choosing us means partnering with a company that prioritizes your success and is dedicated to helping you navigate the complexities of the modern manufacturing environment. Let us help you transform your manufacturing processes and achieve operational excellence.